Electronics Manufacturing Conveyors & Automated Assembly Systems

Posted on

Few industries are as fluid or fast-moving as electronics. The rate at which development and disruption can radically alter the industrial landscape means that electronics manufacturers need to be as flexible as possible in order to survive in today’s market.

In addition to the difficulty of research and design, this creates unique challenges on the manufacturing floor as well. The electronics assembly process demands accommodations for brief product life cycles, the realities of tightening margins, and environmental consciousness.

Modernizing the electronics industry’s conveyor systems is one way to address many of these challenges as once. As one of the world’s leading conveyor manufacturers, mk North America offers an unmatched variety of conveyor and material handling solutions to meet the needs of today’s electronics companies.

If you’re in the business of creating consumer electronics, printed circuit boards, disk drives, engine control modules or other electronic components, mk North America can help elevate your assembly process to the next level by addressing your most pressing needs.

Automation & Robots Can Help Increase Productivity

One of the best ways to optimize manufacturing efficiency in the electronics industry is to increase the use of automation and robotic assembly. This reduces personnel overhead costs and increases output through greater speed and precision.

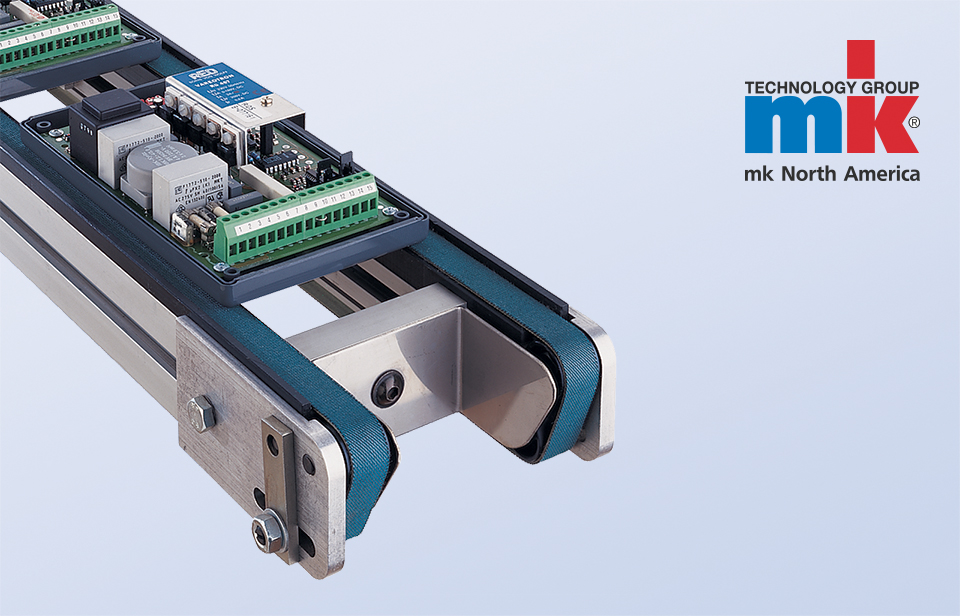

Consider Flat Belt Conveyors

Today’s robotic component assembly lines require conveyor systems with the ability to complement their automated systems. Flat belt conveyors, like mk’s popular GUF-P 2000 low profile conveyor, are perfect choice for transferring components between robot cells. Product staging is best accomplished with cleated timing belt conveyors, which offer precise movement and regular spacing.

For more information on mk conveyors suited for robotic automation, click here.

With short production spans and product life cycles common in the electronics manufacturing industry, industrial equipment that can be seamlessly modified to accommodate new production runs is absolutely necessary. mk North America offers numerous modular material handling systems which are easily adaptable to different production lines over time.

Curved Conveyors

Curved conveyors are ideal to integrate long running sections in transfer and assembly applications. They are also capable of creating space-saving production lines that make better, more efficient use of any manufacturing facility’s square footage.

In addition to our standard systems, mk is also a leader in the creation of custom conveyor systems to meet our client’s specific needs. If you need material handling and assembly automation solutions to meet the increasing demands of electronics manufacturing, contact mk North America by calling (860) 769-5500 or by using this easy online contact form today.