Roller Conveyor Systems

Roller Conveyor Systems Common Uses:

- Bulky Products

- Material Handling

- Packaging

- Pallet-Handling

- Transfers

mk North America offers a wide variety of roller conveyor systems, including gravity roller conveyors, chain driven roller conveyors, and powered roller conveyors. These systems are ideal for products with firm and flat bottoms such as; drums, cases, packaged materials, and other boxed cargo. mk roller conveyors are also excellent for use on pallet-handling lines.

mk's gravity roller conveyors and chain driven roller conveyors are available in both straight and curve configurations. mk's powered roller conveyor is only available as a straight running conveyor.

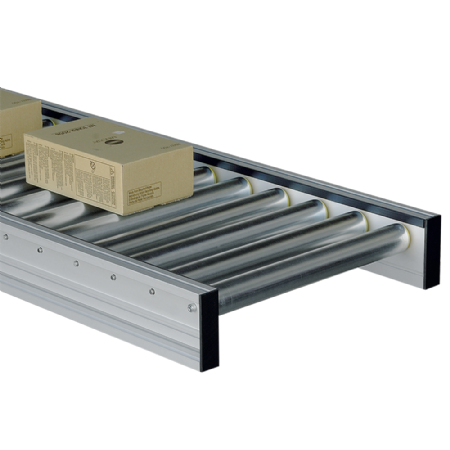

RBS-P 2066/2255

Gravity roller conveyors in different platforms

- Available in three sizes

- Straight and curve sections

- Loads: Up to 250 lbs./ft

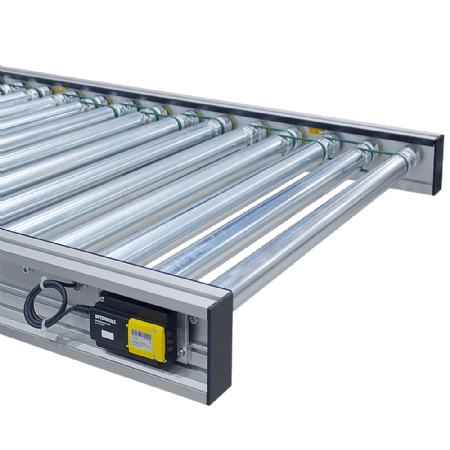

RBM-P 2255

A compact motorized roller conveyor

- Features motorized roller

- Driven with v-belts

- Loads: Up to 50 lbs./ft

RBT-P 2255

This roller conveyor features an external motor

- Chain drive roller

- Straight and curve sections

- Loads: Up to 250 lbs./ft

Types of Roller Conveyors

Gravity Roller Conveyors

The most basic form of roller conveyors, gravity conveyors work by allowing products to slide down the line on plastic or metal rollers. Gravity conveyors can be powered by gravity when set up at a decline, or manually by pushing product when set up on a level surface.

This has the benefit of working without any motorization or power consumption, making gravity conveyors a low-cost option for material conveyance.

mk North America’s RBS-P line of gravity conveyor systems are available with numerous widths, customizable lengths, and both straight and curved modules to provide maximum flexibility and performance.

Individual products in the RBS-P line of gravity roller systems include:

- RBS-P 2065: Features single t-slot and 75 mm deep frame

- RBS-P 2066: Features dual t-slots and 100 mm deep frame

- RBS-P 2255: Features dual t-slots, 120 mm deep frame, and optional side guards

Chain Driven Roller Conveyors

Whereas gravity conveyors work by manually pushing products or utilizing the force of gravity, chain driven roller conveyors are operated by a motorized tangential chain.

Driven chains are integrated into side frames and power rollers via internal bearings and fixed axels, which accommodates both direct drives and slip drives for accumulation.

mk’s RBT-P 2255 chain driven roller conveyors are ideal for large pallets, and allow mounted stops and transfers between rollers for added versatility.

Powered Roller Conveyors

With powered roller conveyors, some or all of a conveyor’s rollers are powered to propel the product down the line. In a typical system, one in nine rollers is powered by an internal motor and linked to the non-powered rollers with a series of O-rings.

Ideal for smaller, lighter loads, mk North America’s RBM-P 2255 powered roller conveyors feature 24-volt powered rollers with included drive cards. Zone configuration is available, with multiple independent conveyor segments integrated to allow product to be segmented, accumulated, stopped, or started at various points along the line.

Looking for custom roller conveyor options?

Contact us online or call (860) 769-5500. Our experienced sales staff will be happy to assist you.