Industry 4.0, The Future Factory & Conveyor Belts

Posted on

Manufacturing has come a long way since the inception of the industrial revolution in the 1800's and the rise of machines and factories. Today, new technologies continue to reshape how we live and work. The idea of robots working along-side human operators is no longer something out of a science fiction movie. Machine learning and artificial intelligence have made automation and efficiency possible for factories of all sizes.

The Future Factory

On the quest to do more with less, we’re now moving into the next generation of manufacturing known as “Industry 4.0.” Here, new business models where everything is connected, from sensors to the ERP systems, work together intelligently and efficiently.

The smart factory leverages IoT technologies so that machines can communicate in real-time with each other and human operators through wireless connections. Not just understanding the tasks at hand, but learning from them and improving processes make the “Future Factory” something manufacturers can no longer ignore.

As with any new technology, some stakeholders and companies are apprehensive to take the dive. There are risks with relying on network connections and fear of job losses however there are also great benefits to consider.

Less Downtime, Better Quality

Being able to predict and prevent unscheduled downtimes in the production cycle is a key benefit of Industry 4.0. By monitoring and having insights into everything working in the operations, it’s possible to know if a machine is experiencing issues that could cause delays or errors in production. Once recognized, notifications of the status and location of the issue can be sent to the appropriate people in real-time. As machines analyze and leverage data they can work faster and more accurately and deliver more consistent products and quality.

Improved Labor

While there is fear of robots replacing human workers, the reality is the just opposite. In the Smart Factory, humans are still needed to operate some of the robots (including traditional machine tool operations like CNCs) as well as troubleshoot and repair them. In the future, as these tasks become automated, collaborative robots will still work alongside human operators and perform dangerous tasks or mundane and repetitive jobs in a more efficient and cost effective way.

Optimizing your production lines in 2018 will require cooperation from both suppliers and manufacturers and that automation and connectivity also work in unison with hardware, firmware and software solutions to maximize potential.

Where Conveyors Fit In

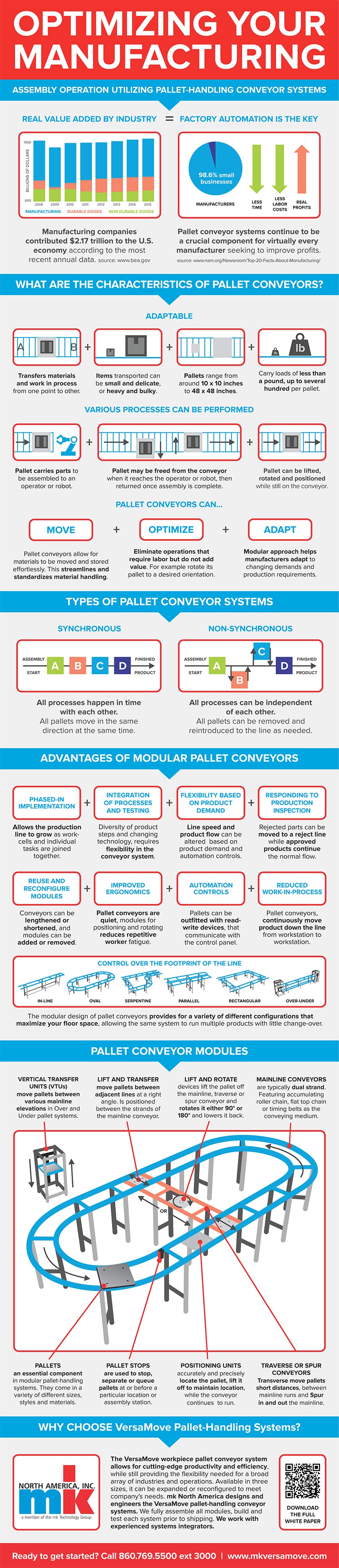

Conveyors have become a key element in all automated facilities and applications today. They help to transport materials, take products from one location to another, and are also responsible for orientating and metering out product. Conveyors are also responsible for providing buffering and staging between processes, back-lit conveyors aide in vision lighting for robotic picking units, and so much more.

Pallet conveyor systems are helping manufacturers to improve profits. The versatility in how these systems can be configured makes them perfect for an array of industries and operations. Take a look at the below infographic for a review of the many benefits pallet conveyors are bringing to the factory of today and the future.