Problem Defined

The Necessity for a Difficult Conveyor Configuration, Tightly Constrained by the Product It's Moving

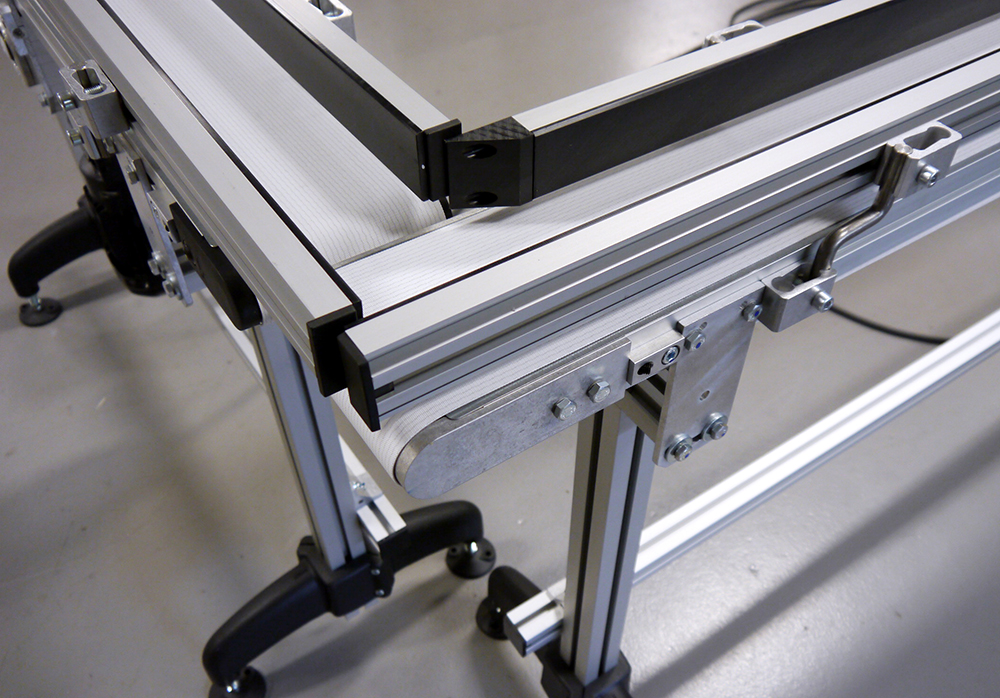

A global leader in automated material handling systems came to mk for a part-handling conveyors between a robot and a buffering zone, mk was up to the task. The conveyors needed to be able to convey the products in a U-Configuration as simply as possible, while taking into account the small footprint of the part. The conveyors also needed to allow for product to accumulate.

mk North America's Custom Solution

Customizing Guide Rails and Conveyor Systems in Collaboration with Customers

Designing the three conveyor U-shaped system on mk’s GUF-P 2000 flat belt conveyor platform allowed for the ultimate in flexibility. The GUF-P 2000 is mk’s leading conveyor product line and offers the most drive and idler options in the industry. Combined with mk’s aluminum extrusion line, the engineers at mk were able to develop custom side rails to guide product around 90° corners. They also developed and designed, using mk extrusions, nesting plates for product placement as well as system supports and sensor and controls mounting.

Since mk stocks all of the components for the accessories and conveyors, mk was able to deliver a complete solution at the right price and the right time (lead-time was approximately four weeks). Working side by side with their customers, mk is able to participate in design reviews and developments, which makes mk truly a conveyor solutions partner.

mk North America is a premier supplier of low profile aluminum framed conveyors. Offering more than 20 standard conveyor platforms, mk has a solution for nearly every industrial, manufacturing or assembly conveyor requirement.

mk is set apart from competitors in their ability to modify, customize and make truly adaptable conveyors for each customer’s specific requirements.

Customer Benefits

- Standard conveyors in a unique configuration

- Standardized conveyors allows for the fastest turn around on the initial project as well as future spare and replacement parts

- A purely mechanical design for the product transfer around corners reduces failure points in the line