Problem Defined

Inspecting Individual Round Batteries

An electric vehicle battery manufacturer needs to join together individual round battery cells in order to make battery modules. However, before this can be done, the round cells need to be individually inspected, via a fully automated machine, in a separate receiving area. An existing robot will then remove groups of round battery cells from their packaging. A new conveyor line is needed in order to separate the batteries, so they can be ionized against electrostatic charge.

From here, the batteries are placed into trays, each battery having its own compartment in the tray. After this step, the batteries then need to undergo a number of rigorous, inspections. The trays are designed to carry the batteries between the various automated inspection stations, and the conveyors need to provide a means in which rejected parts can be ejected from the line. The trays are to hold 14 round cell batteries and must pass through all the inspection stations within 15 seconds.

From here, the batteries are placed into trays, each battery having its own compartment in the tray. After this step, the batteries then need to undergo a number of rigorous, inspections. The trays are designed to carry the batteries between the various automated inspection stations, and the conveyors need to provide a means in which rejected parts can be ejected from the line. The trays are to hold 14 round cell batteries and must pass through all the inspection stations within 15 seconds.

mk North America's Custom Solution

Battery Inspection Conveyors - Tray Handling Conveyors

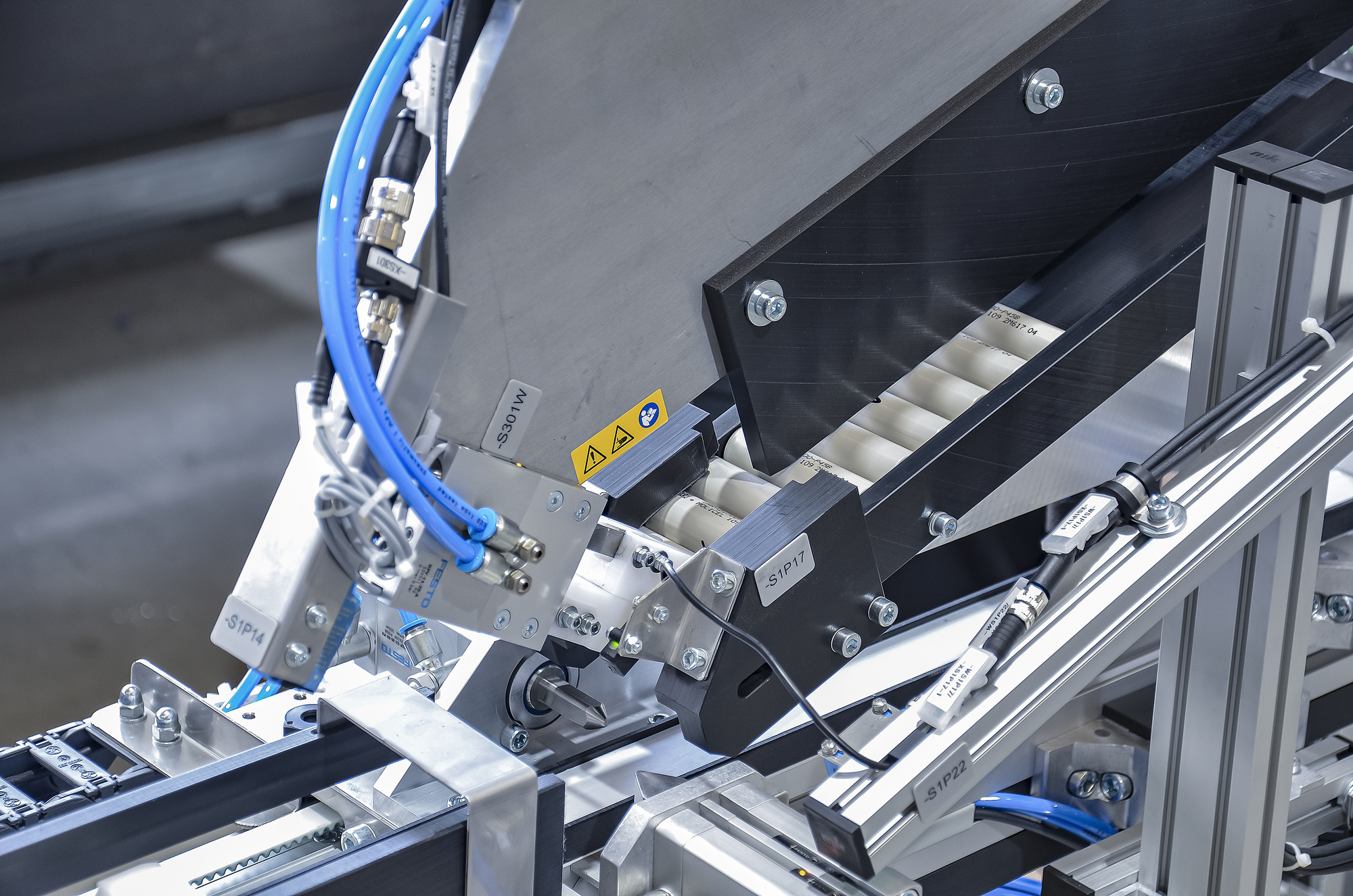

The high level of precision provided by mk's ZRF-P 2040 timing belt conveyors, paired with part sensing and system integration, ensures that the automated inspections will be carried out reliably and steadily.

The high level of precision provided by the ZRF-P 2040 timing belt conveyor ensures that the automated inspections will be carried out reliably and steadily.

The high level of precision provided by the ZRF-P 2040 timing belt conveyor ensures that the automated inspections will be carried out reliably and steadily.

A robot placed the round battery cells onto a ramp, from there the batteries are separated and they slide into the waiting compartments on the tray. After the round battery cells have been inspected, they are unloaded from the trays and the trays return to the ramp position to be reused. Due to the fast cycle time and limited floor space a shuttle was constructed using mk's LZR linear module for the tray return. The conveyor and the linear module run parallel to each other.

Customer Benefits

- A solution that provides the customer with the reliability, repeatability and high precision that are necessary to meet the mechanical accuracy requirements in this particular scope of work

- A single source custom solution for all mechanical components (conveyor and linear module)

- Ability to meet the demanding short cycle time, while maintaining high throughput rate

mk Products Featured