Webinar: Modern Conveyor for Tomorrow's Automation

In April 2022, mk North America, in partnership with Design World a WTWH Media company, hosted a webinar on "Modern Conveyors for Tomorrow's Automation".

In April 2022, mk North America, in partnership with Design World a WTWH Media company, hosted a webinar on "Modern Conveyors for Tomorrow's Automation".

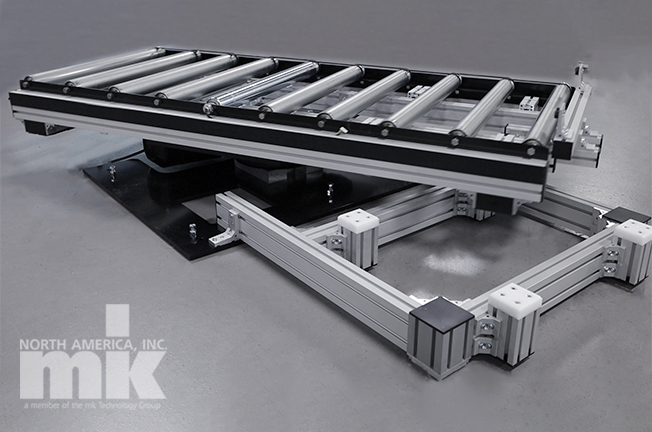

What makes a conveyor system custom?

Is it the ability to select a specific length or width or both?

Is it being able to have a belt that can withstand extreme temperatures?

Is it a conveyor that can justify the product, carry it over a gap, and aide in visual inspection?

Yes! Yes! and Yes!

Custom conveyors are all these things and so much more. Continue reading to learn all about custom conveyor solutions.

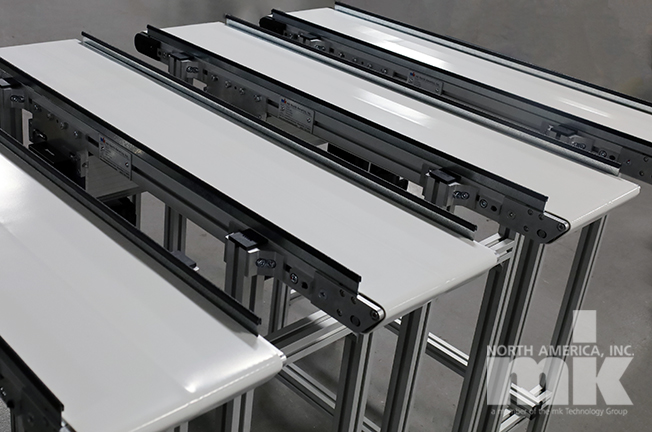

mk North America offers six different types of belt conveyors; some are designed for very specific uses and others can be used in a wide variety of configurations. But regardless of whether or not a conveyor has a specific use or not, all mk belt conveyors are highly customizable – making them the perfect solution for many industries and applications. In this article we’ll compare and contrast the various mk belt conveyors – and we’ve included a chart to help make selection easier.

Back in 2016, we looked at over under conveyor systems using mk belt and high-load conveyors. But times have changed, and new technologies have been developed. In this article, we’ll explore two of these newer conveyor types, learn their differences and similarities and see how they stack-up against more traditional over under conveyor models.

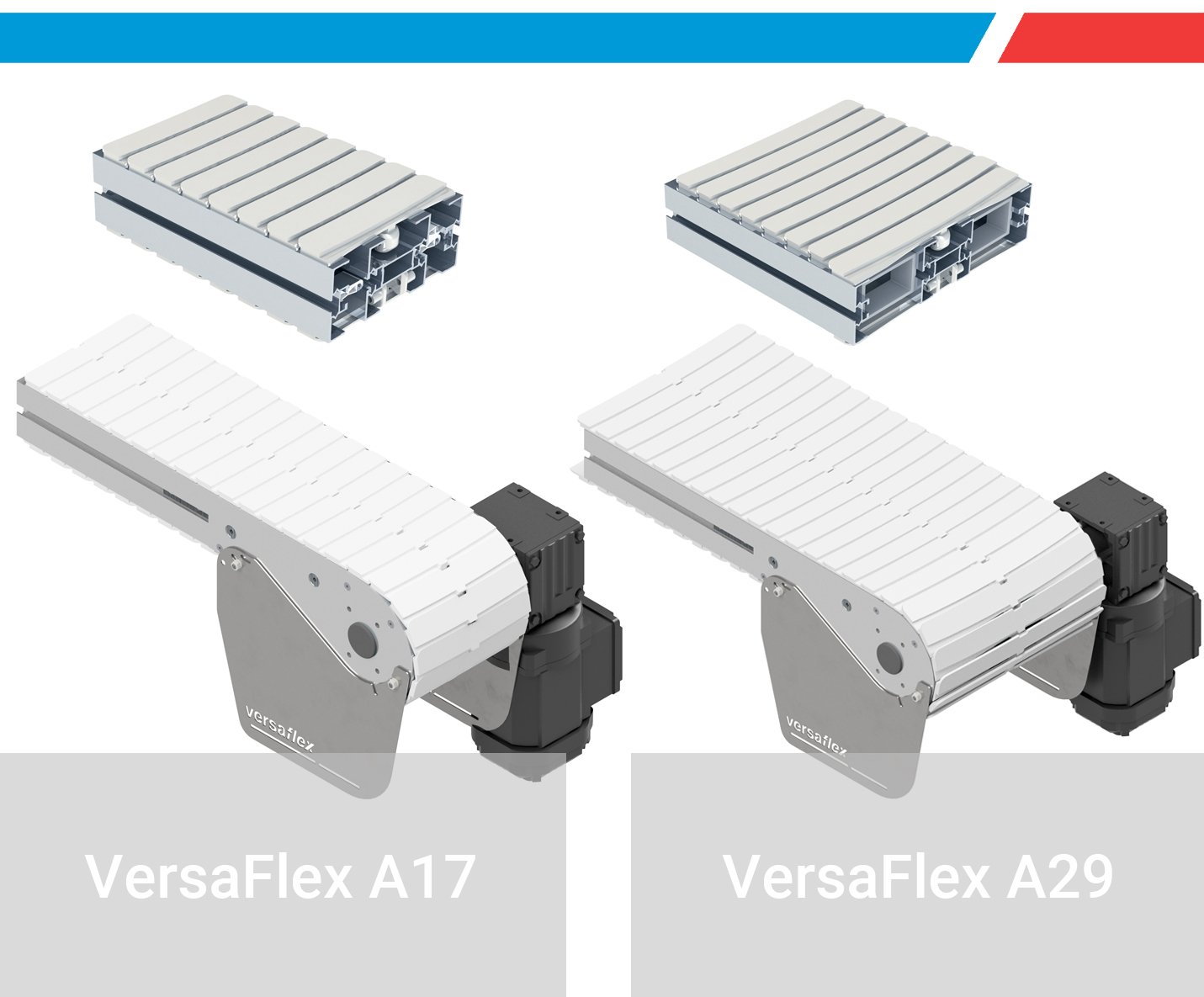

mk North America announces two new conveyor width options for the VersaFlex flexible chain conveyor line. This is a copy of the original press release which first appeared on ABNewswire September 14, 2021.

In a previous post, we explored various product characteristics and how they affect conveyor selection type. One of the specific questions asked was “Does the product have a leading edge that should be maintained during conveying?” In this post we’re going to dive deeper into that question and unpack what the leading edge is and how to maintain it.