Maintaining Leading Edge in Conveyors

Posted on

In a previous post, we explored various product characteristics and how they affect conveyor selection type. One of the specific questions asked was “Does the product have a leading edge that should be maintained during conveying?” In this post we’re going to dive deeper into that question and unpack what the leading edge is and how to maintain it.

Conveyor Leading Edge — What is the "leading edge" in conveying?

The leading edge refers to the edge of the product that travels conveyor first. An analogy would be to consider your car to be the product, the road it’s traveling on is the conveyor – in this instance, the front bumper is the leading edge. In the car analogy, it’s important for the leading edge, the front bumper, to always come first in order to keep the product (the car and contents) safe.

The leading edge should not be confused with a critical edge. The critical edge of a product is one that may require special attention, it may be the edge that always needs to run along the right-hand side of the conveyor (such as how the passenger side of the car should always orientate to the curb) for assembly or testing to take place, as an example. A critical edge may also be an edge that cannot be marred or touched. If there is a critical edge, this may have an impact on the leading edge.

Maintaining the Leading Edge in Conveyors

Maintaining a product’s leading edge on a simple conveyor that conveys the product from point A to point B in a horizontal linear fashion is simple – simply use a conveyor type and rails as necessary to maintain the product orientation. But what about a product that needs to travel around corners or change elevations, or a production line that needs to double back on itself? Then the conveyor system or conveyor line needs to be designed in such a way that the leading edge is maintained.

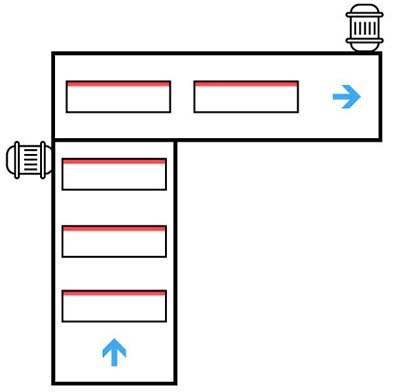

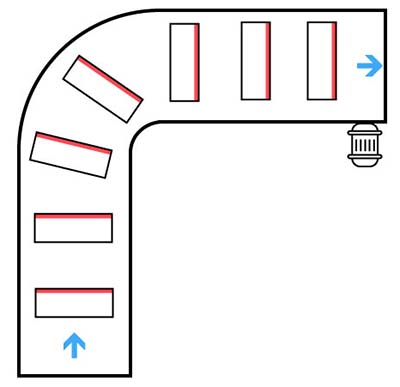

In the most basic forms of conveying product flow can change direction simply by discharging the product off the side or end of one conveyor and onto the side or edge or another – see illustration below.

However, this type of transfer will not maintain the leading edge. In instances where the leading edge of the product must be maintained then a conveyor system which includes curves must be used. These curves can be standalone units, such as mk’s KGF-P 2040 flat belt curve, or they can be integrated into the conveyor design or systems like mk’s VersaFlex line of tabletop chain conveyors or mk’s KMF-P 2040 plastic modular belt conveyor.

Maintaining the Leading Edge with Pallet Conveyors

If the product is being conveyed on a pallet, maintaining the leading edge may be very simple depending on the pallet size. Smaller pallets and/or pucks can be conveyed using mk's VersaFlex P08 conveyor system. This combines all of the benefits of a flexible chain conveyor with all of the capabilities of a pallet-handling conveyor system - this includes maintaining the products leading edge via curve conveyors.

Medium and large pallets, typically conveyed on an mk VersaMove system can have their leading edges maintained using a variety of Lift and Rotate modules. In fact, Lift and Rotate modules are also ideal for spinning the pallet and product, which allows the product to have various sides worked on. These modules offer versatility to a conveyor line and can greatly expand what can be done to the product while on the conveyor.

Working with mk

That said, there are many conveyor applications in which there is no need for a leading edge, in fact not having a critical or leading edge is more common than having one. However, in instances in which there is a leading edge it is important to identify that during the quoting process - as this will save time and money.

When you work with mk North America you are working with a team that will help you identify the critical characteristics of your product and process. The mk team will then go on to help select not only the best conveyor for your application but also the best solution.

To get started on your conveyor application fill out the form below and a member of our team will be in touch.